Coal Scuttle

Object

Today we’re looking at the history and treatment of a Victorian coal scuttle which is part of Beamish Museum’s collections. It was acquired by Beamish Museum from a 1930’s school in Fenham in Newcastle.

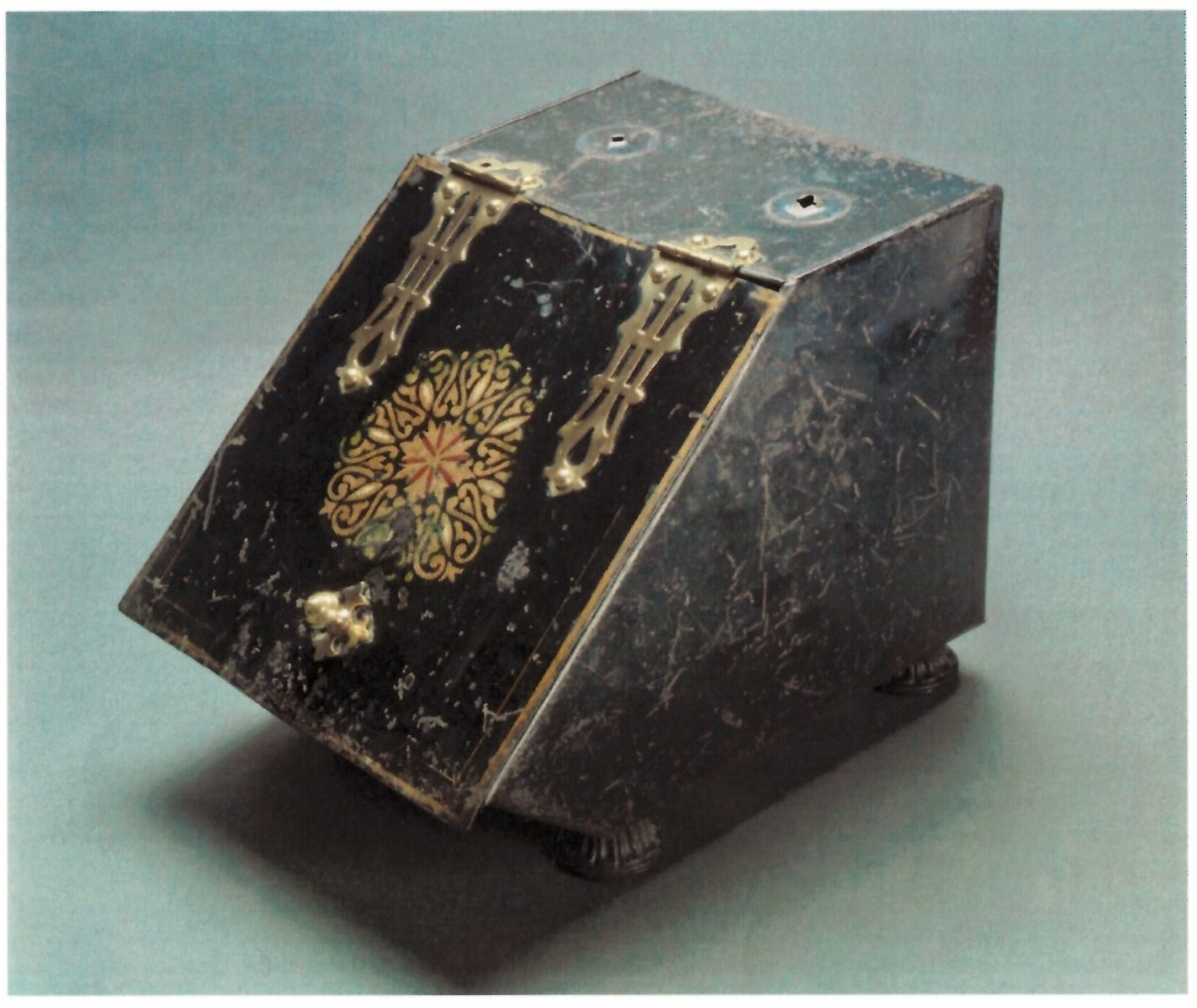

The object is comprised of two parts; a lidded, slope fronted outer ‘box’ with a lid that opens to reveal an ‘inner’ box with two handles that facilitate its removal. It’s possible the coal scuttle originally had a handle on the exterior due to the presence of two perforations on the exterior, one of which still contained a screw. A shovel holder is also attached to the back of the outer box, though the shovel is missing. The top of the coal scuttle displays a decorative golden flower motif.

The emergence of the coal scuttle as a domestic item is synonomous with technological advancements of the Industrial Revolution (namely steam power) which enabled deep mining and lead to coal replacing wood as the main source of fuel for both industry and domestic life in the 18th and 19th Centuries.

Efficient household management dictated bulk buying of domestic provisions including coal. While cellars and a coal shed could be used for long term storage, it was also necessary to keep smaller quantities indoors for immediate use. A suitable receptacle for carrying the coal from where it was stored, and that could also be kept by the fire, lead to the development of the coal scuttle.

As with many household items, the elaborate nature of the object often depicted the wealth of the owner. The more decorative the coal scuttle, the higher the status of the house that it belonged to. For the poorer households, functionality was more important than design, so they were more likely to have simple, more practical coal buckets from which to pour coal.

The focus on domestic life and the value ascribed to good housekeeping and cleanliness within the Victorian home, resulted in the emergence of scuttles with closeable lids. This development minimised the spread of coal dust and banished the unsighly coal from view. Similar coal scuttles to the one from Beamish, would suggest that this object originates from the Victorian period.

Condition

- Evidence of dust and dirt on the surface

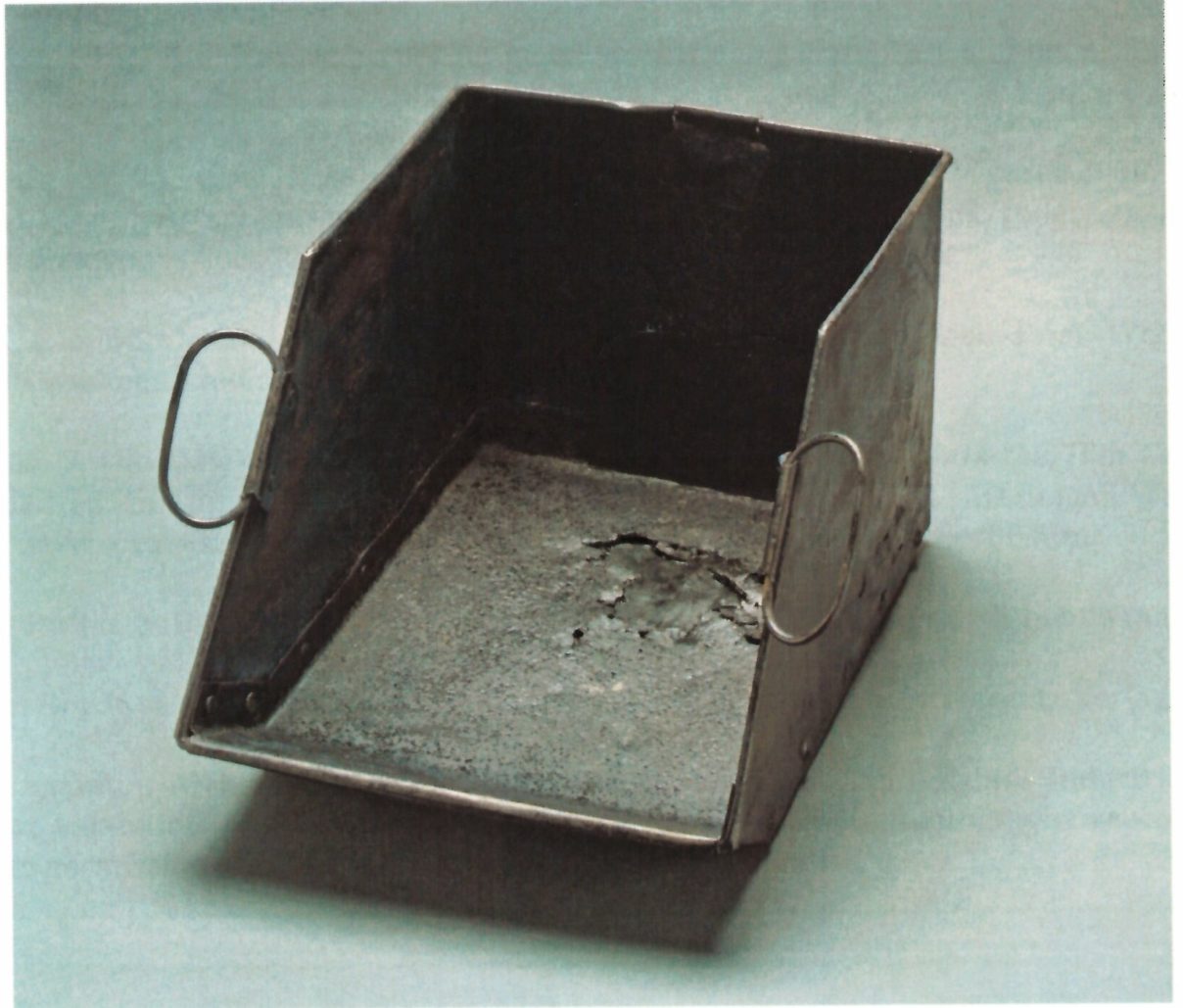

- Severely corroded on the underside of the interior box, with substantial areas of loss

- Right hinge is loose

- Flecks of white paint on the surface

- Evidence of scuff marks

- Possible missing handle from the exterior

- Evidence of a missing foot

Conservation

On initial examination it was clear there was still evidence of coal dust in the interior chamber; this was carefully extracted and stored in a labelled polythene bag in case analysis was desired in the future. Following this the surfaces were gently brushed and vacuumed in order to dislodge dust and dirt. For more ingrained surface dirt solvent cleaning was implemented using dampened cotton wool swabs.

Areas of surface corrosion were removed using a combination of abrasive cleaning methods, including a stiff bristle brush and a glass bristle brush. This successfully removed the corrosion without damaging the surface underneath. Throughout the cleaning process, as dirt and corrosion were removed, evidence of use emerged, including scratch marks on the interior which were consistent with the inner box being removed and replaced on a regular basis.

To remove the flecks of white paint from the exterior of the coal scuttle, an appropriate solution was applied to them using cotton wool swabs in order to soften the paint. They were then removed mechanically from the surface using a scalpel under 2x magnification for precision and to avoid further damage. To remove the areas of tarnish and corrosion from the brass hinges, a mild abrasive was applied and then any excess was removed using a suitable solvent.

As the surface of the lid had a decorative design, solvent tests were implemented in order to determine what would remove the dirt without removing the paint itself. Once an appropriate solution was found, the surface was cleaned using cotton wool swabs and on completion the edges of transfers beneath the decoration of the centeral design and the bordered motifs became apparent.

The gold paint within the transfer was found to be dissolvable in acetone, which suggests an additional paint was used on top of the transfer. This could suggest that the transfer was only the outline of a flower motif and that it was then painted in by hand using a gold paint.

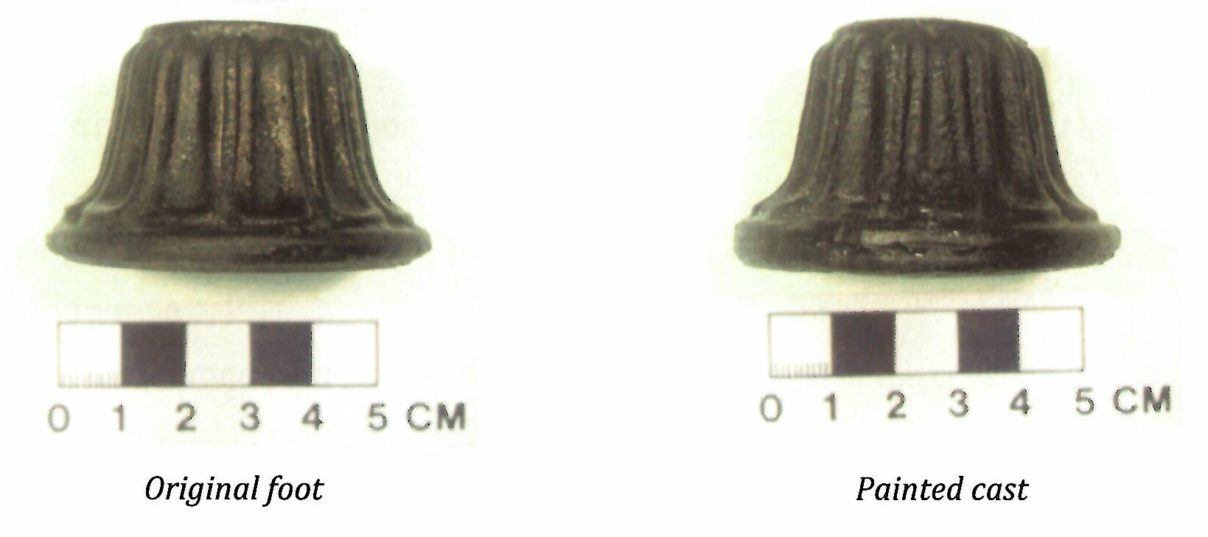

As several of the feet from the coal scuttle were missing, the decision was made to replicate replacements in order to assist with stability. A mould of the only remaining foot was made using heat resistance silicone rubber to which molten low melt metal alloy was added. This was left to cool before being extracted; it was then filed to remove excess metal and a hole was drilled in the top so that it could be attached to the exterior. The casts were then colour matched using acrylic pigments to match the original foot before being secured to the base of the coal scuttle.

The area of missing surface material on the interior box of the coal scuttle was repaired by applying aluminium mesh between the two layers of original sheet metal and securing it in place using an epoxy resin for strength. A combination of fibreglass matting and resin was then applied to the missing areas in order to inprove stability and provide strength; this was done in layers in order to build up the fill. Finally, a layer of colour matched Japanese tissue was applied over the fill areas in order to minimise obtrusiveness.

Although there was a high probablility that there had originally been a handle on the exterior of the coal scuttle, because there was no surviving evidence the decision was made not to replicate it, however suggestions for how the coal scuttle handle might have looked were considered.