August ’22

Jemmy

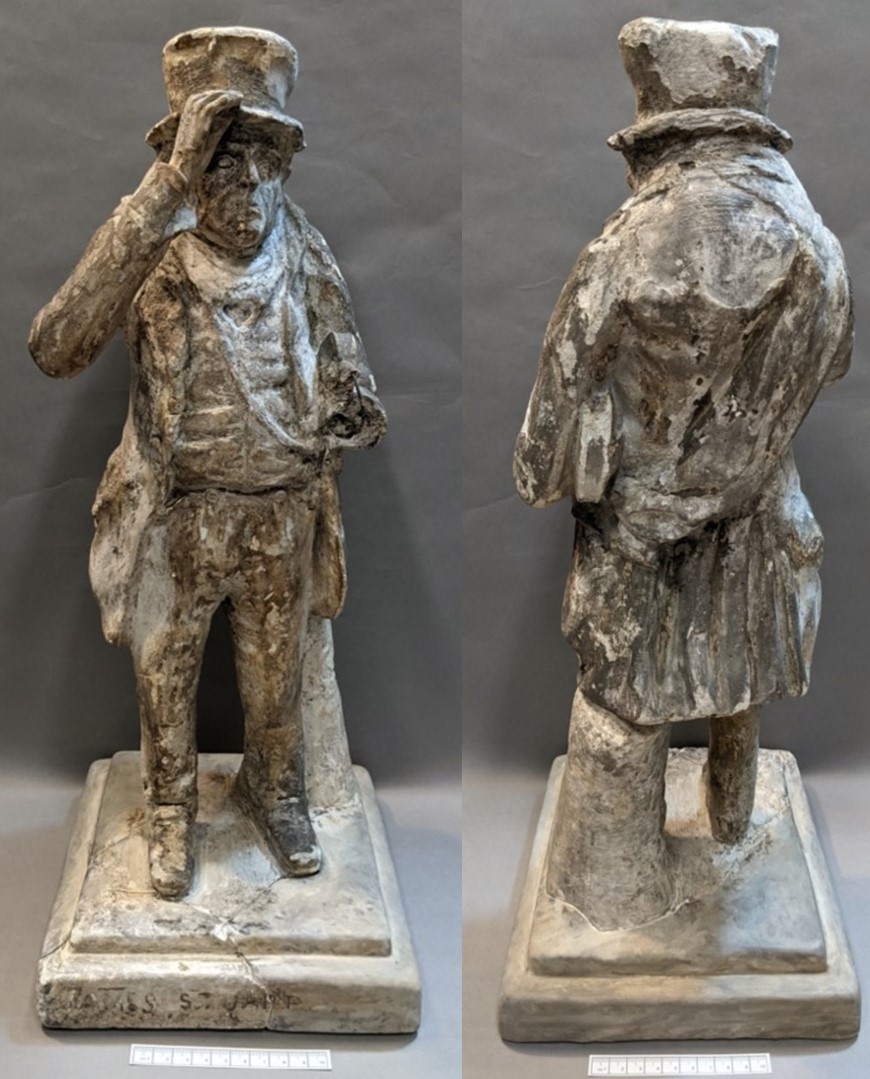

The object is a plaster statue, which forms part of the collection at Durham Castle. It is a scaled copy of a life-sized stone statue erected in Berwick around 1841, depicting ‘Jemmy Strength’, otherwise known as James Stuart, a well-known local figure and folk hero. The statue depicts Jemmy doffing his top hat and carrying a fiddle under his left arm, whilst also noting his hunched back and somewhat peculiar appearance.

The plaster copy was created at some time in the latter half of the 19th century and is noted in the University College’s 1924 inventory. There are records of it being on display in both the Senate Room lobby and passageway area of Durham Castle but it has since been in storage for many years.

The statue is made out of two layers of gypsum plaster (plaster of Paris), the outer layer is a bright white and the interior layer is a pale pink. The cast has been formed around a metal armature, and possibly coated in a protective surface layer. Whilst it is not clear exactly how it was made, it was most likely cast by coating the interior of the mould with a layer of fine plaster, then pouring in a lower quality plaster. This would give the statue the high-quality finish of a fine plaster whilst also saving on costs.

The mould itself was likely made up of several pieces, which would have been secured together during casting and then removed individually once the plaster had cured. Given some slight differences between the photograph of the original stone statue and the plaster copy, most notably the position and shaping of the right hand, it seems reasonable to assume that the plaster statue was cast from a hand crafted copy of the original made at the desired scale.

Condition

- Large areas of the base were missing making the statue unstable and unable to stand upright

- Several sections of the base had detached

- There were signs of rust on the metal armature

- The object had visible dirt on the surface.

Conservation

Prior to cleaning, a mount for the statue was created so that it would be more stable and less vulnerable to damage during cleaning. To do this the statue was placed upright at the correct level (calculated using the fragment from the base), and secured using a clamp and sandbags. The centre of the base was supported by a cast cylinder of Milliput adhered to the underside.

The edges of the base and the base-fragment were isolated using an appropriate solution before being adhered to the rest of the base. This was done so the fragments could be removed easily at a later date if necessary.

To recreate the missing pieces of the base, a template was made using plastazote. The plaster base and plastazote were then covered in clingfilm and Milliput was applied to the foam template. This treatment was undertaken in four sections, with each section being left to cure before the next was started. The Milliput was sculpted to resemble the original dimensions and shape of the base. Once the desired form had been achieved, the Milliput was smoothed to a fine finish using water.

After the pieces of Milliput had fully cured, they were removed from the base and sanded to form a smooth finish. Finally, they were washed to remove any dust from the sanding process. The new sections of base were adhered to the original base with a suitable adhesive. Once cured, the joins between the four sections were covered with a new layer of Milliput to created a completely smooth base with no lines or cracks. The Milliput base sections were then colour matched using acrylics.

The statue was then cleaned using a specific cleaning gel, which was applied using cotton swabs. Any residue from the gel was removed using swabs of ethanol. This process was completed in sections, with only small areas of plaster exposed to the cleaning gel at a time.

The rust on the exposed armature was treated by first removing any loose corrosion with a brush. Iron staining visible on the surrounding plaster was removed using dry cleaning methods. The iron wire was treated with a rust converter in order to stabilise the corrosion. It was then treated with an appropriate consolidant to help prevent further corrosion.

Stay tuned for next month’s object!