January ’22

Plastic Doll

This object was received from Beamish, the Living Museum of the North in June 2021. The doll was gifted to the donor in the 1950s, then donated to Beamish in 2014. It is unclear whether the clothing is original to the doll or was added later. Conservation work was undertaken to prepare the object for display and handling at Beamish, where it will become part of the new ‘1950s Town’.

The doll is a Palitoy ‘Patsy’ doll first produced in the 1950s. Various iterations were produced throughout the decade and into the 1960s. This doll would have been an expensive gift at the time, given the innovative nature of the voice box and crying mechanisms. The earliest ‘Patsy’ doll was advertised in 1950.

These dolls were manufactured using vinyl (PVC), often described as ‘rubber’. Liquid plastic would be injected into reusable moulds, then set (by cooling) into the desired shape. PVC is commonly used for injection moulding and has been produced on a commercial scale in the UK since the 1940s. Injection moulding was a typical manufacturing method used by Palitoy at this time.

This object is indicative of cultural change in the 1950s following the post-WW2 arrival of West Indian immigrants to the UK (e.g., on the HMT Windrush Empire). Toys began to cater to wider groups of people, although black dolls often appear to caricature the individuals they represented.

Condition

- Plasticiser can be seen to be migrating to the surface of the doll causing the surface to be tacky

- There was physical damage to the neck joint which had almost completely failed.

- Splitting along the joins behind the ears could be seen

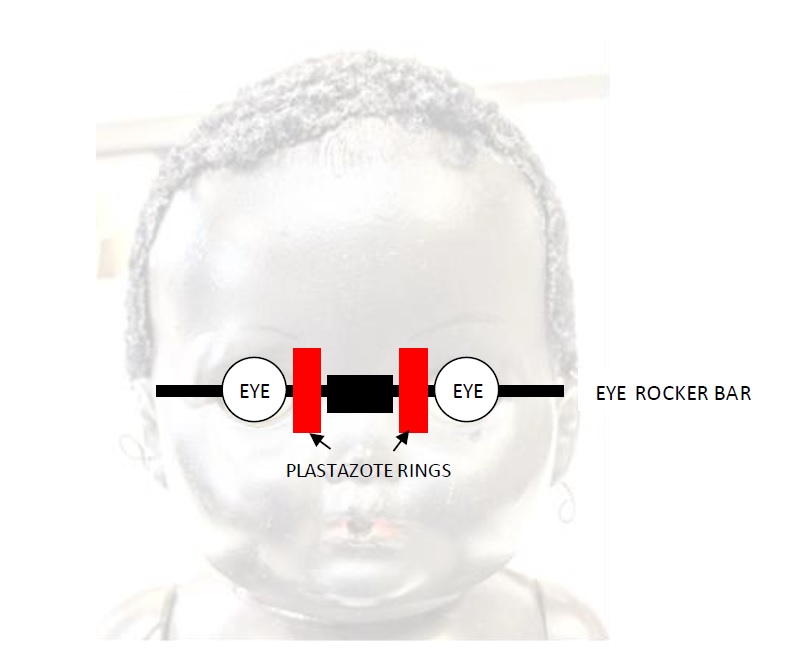

- The eyes have moved out of place and were loose on the rocker bar

- The wig was lifting at the edges and has suffered surface material loss

- The surface of the doll was covered in dirt

Conservation

The plastic surface was wet cleaned using a microfiber cloth with deionised water and an appropriate surfactant to remove ingrained surface dirt and migrated plasticiser. During cleaning wetted areas were patted dry using a separate microfiber cloth, then surfactant residue was removed using deionised water, and the plastic surface was again patted dry.

In order to prevent the eyes from moving around in the head, plastazote rings were inserted onto the rocker bar, on the inner edge of each eye. This successfully held the eyes in place.

The interior of the broken neck joint was cleaned using deionised water in order to ensure a clean join for adhesion. The neck join was adhered using an epoxy resin in order to achieve the strongest join possible. Once cured, gaps in the join were filled using the remaining epoxy toned with powder pigments to match the colour of the plastic. This resin was also applied to the crack behind the proper left ear (the larger of the two cracks behind the doll’s ears and thus a greater concern to the structural integrity of the doll).

The lifting edges of the wig were re-adhered using a suitable adhesive, applied using a brush. The edges were held down using sandbags, and cushioned with acid-free tissue paper before being left to cure for 24 hours.

Stau tuned for next month’s object!