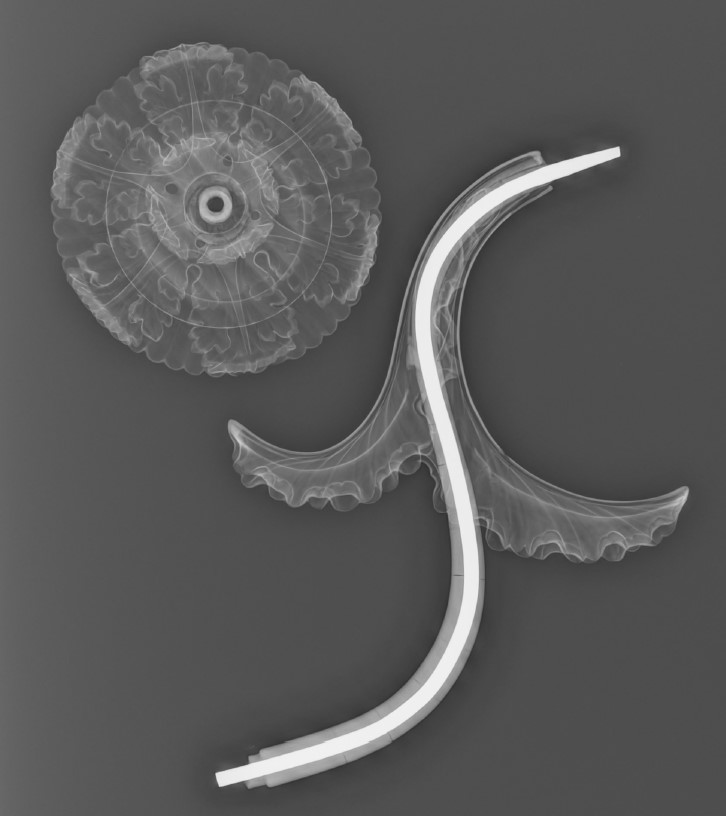

Gilt Sconce

Object

This object is one of three matching gilt wood candle sconces from Kiplin Hall. Decorated in typical neoclassical style with Greek acanthus leaves, this sconce was likely made in the late 1700’s to the early 1800’s with the neoclassical revival in the Regency era.

Neoclassicism was an art style that began in the 1760’s and lasted until the 1840’s. It was inspired by new archaeological discoveries in Greek and Roman antiquities. The style focused on antique motifs (like acanthus leaves), simplicity, harmony, and idealism.

Candles were expensive at this time, and being able to light a house at night was a sign of wealth. Likewise, the fine workmanship and gilding of this sconce indicates the high social status of Kiplin Hall.

Condition

- Evidence of dirt on the surface as well as bird excrement

- There is wax in the candle holder space

- There are several areas of lifting gilding

- Signs of surface material loss at the tip of an acanthuys leaf

- The iron armatuure is showing evidence of surface corrosion

- The rondelle is detached from the stem

Conservation

In order to prevent any further loss of gilding while cleaning took place, the areas which were flaking were consolidated with an appropriate solution.

A variety of solvents were tested on the surface of the gilding to determine which would remove the surface dirt and bird excrement, without damaging the gilding. Once a suitable solvent had been identified it was carefully applied to the surface using cotton wool swabs. This was successful at removing surface dirt and most of the bird excrement, though some stubborn areas remained. As no other solutions could be used to remove the bird excrement, mechanical methods were employed. A micro scalpel was used under a microscope to remove the remainder of the bird excrement successfully. This method also proved to be the most appropriate for removing the candle wax residue.

As the metal armature was in such close proximity to organic materials, the decision was made to treat the corrosion chemically. A rust converter was chosen and applied to the surface to make the corrosion chemically stable, preventing further deterioration. Using a rust converter was deemed to be more controllable than mechanically removing the surface corrosion.

The decision was made to cast a replacement for the missing section of leaf. Siligum was used to make a mould from an unbroken leaf. Milliput was placed into the mould, then pressed onto the loss, with a protective barrier of clingfilm between. This would help to achieve a smooth join. The cast piece was shaped and smoothed to mimic the surrounding surface and adhered in place using an appropriate adhesive.

The leaf cast was then gilded to blend with the surrounding surface. Powdered pigments were brushed over the fills to mimic the bole colour under the original gilding. An acrylic ‘size’ was applied and left to dry before gold leaf was applied to the areas. The gilding was colour matched using watered down acrylic paints to help it look aged.

Finally, the two sections of the sconce were coated using renaissance microcrystalline wax to help protect the surface. They were then readhered together using a suitable adhesive.