Izal Mint Tin

Object

All is going well in the conservation department with the new batch of students settling in nicely. A couple of them wrote a nice piece about the copper alloy coins they’ve been working on and hopefully we’ll get a few more posts from them through the year. Today we’re going to look at another object that was worked on over the summer by one of the students who’s now gone on placement. The object in question is an Izal mint tin from Beamish Museum.

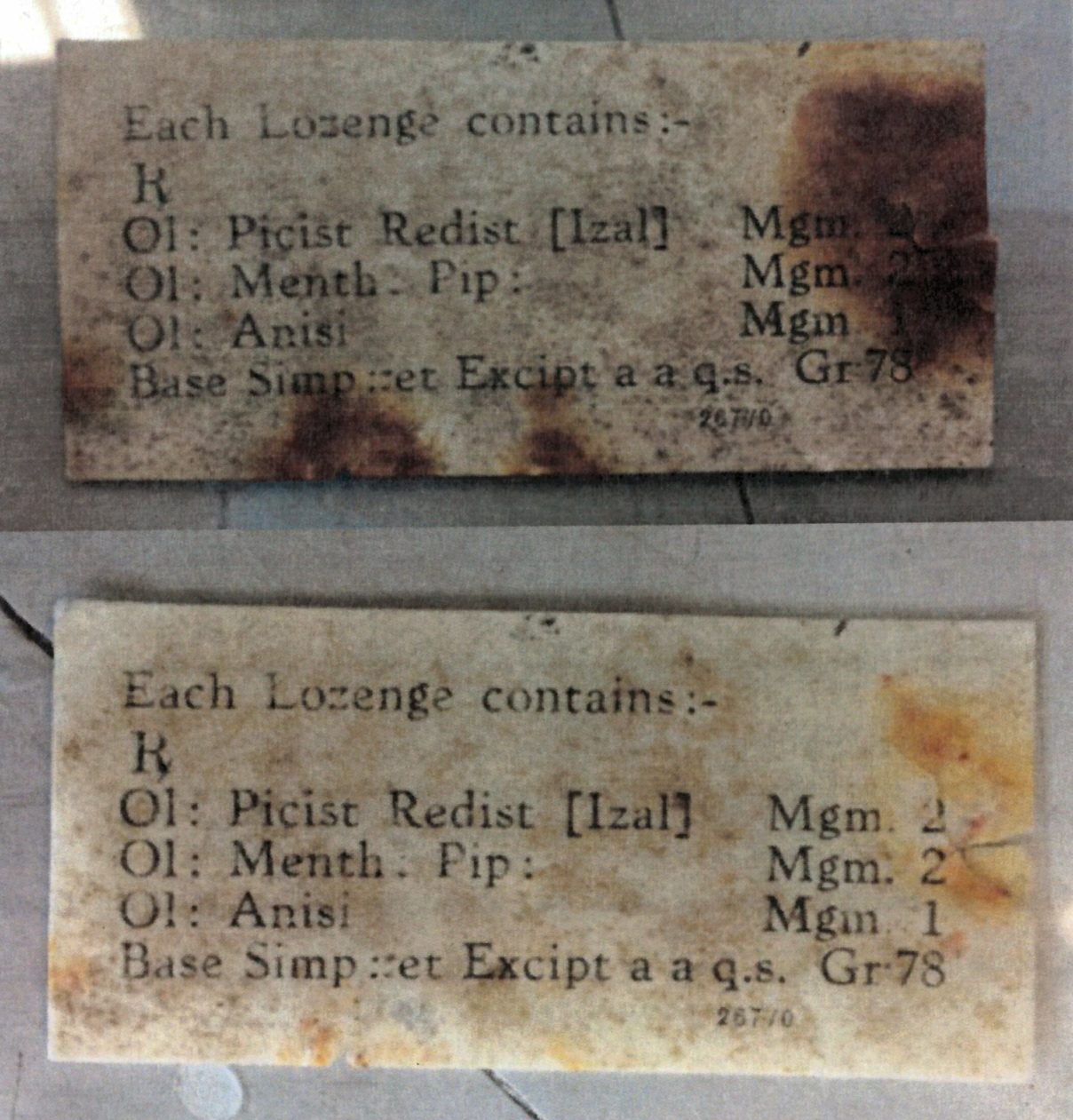

The tin has three labels on the surface; one on the top, which displays the name of the contents, one inside, which provides instructions for how to take the losenges and one on the bottom, which states what each losenge contains. Two of the labels also have the manifacturer’s name, ‘Newton, Chambers and Co’ written on them.

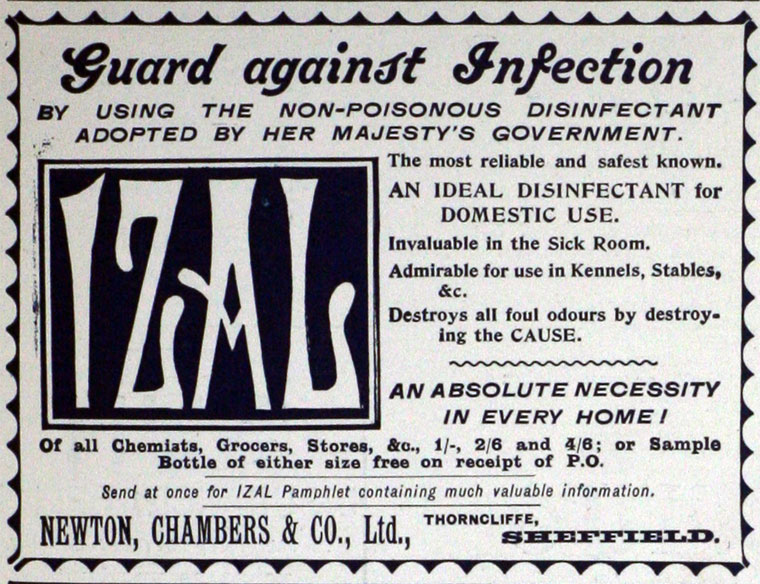

George Newton and Thomas Chambers bought the mining rights to the Thorncliffe valley in 1973 and set up the Thorncliffe ironworks. They appointed an analytical chemist to look at the oil produced by coal in the coke ovens, which resulted in a germicide oil known as a non-poisonous disinfectant. Known originally as Thorncliffe Patent Disinfectant it was soon renamed Izal. There was a total of 137 different Izal products produced and included losenges, disinfectant, toilet paper, soap, shampoo and shaving foam. Izal products continued to be produced until 1973 when the Izal subsidiary was sold.

Izal was part of a new generation of chemical products that marked a significant change in society and its attitudes to medicine and public health. Advertising focus shifted during the late 19th Century from curing illness and infection to preventing it through antisceptics and these products were more readily available which allowed people to take control of their own health.

Condition

- Surface dirt on the metal and paper components.

- Areas of missing paint on the tin.

- Small dent in the lid of the tin.

- Iron staining on the paint and paper.

- Iron corrosion breaking through the paint.

- Paper label lifting.

Conservation

Both the metal tin and the paper labels were surface cleaned using plastic eraser in order to remove dirt and discolouration. This proved very effective at removing dirt while leaving the paper and inks undamaged. To fully treat both the metal tin and the paper labels, it was decided the labels would need to be removed. This would ensure the metal corrosion beneath the labels could be treated and the labels themselves could be treated and stabilised. Testing was carried out and it was found that the labels were attached using a water soluble adhesive and as the inks weren’t affected, water was used to safely remove them.

The paper labels were then washed in deionised water for several days, with the water changed twice in the first day and daily thereafter. This removed more of the dirt but didn’t fully remove the iron staining, which was still fairly noticeable. As a result testing was carried out in order to determine the best method for removing the iron staining and after a suitable treatment was determined it was applied to the paper labels and found to be successful on two of the three. Unfortunately the green pigment on one of the labels was sensitive to the chemical used in the treatment for removing iron staining and so it was decided this label would not undergo further treatment.

The iron corrosion on the surface of the metal tin was removed using an appropriate abrasive material and was found to be successful at removing the dirt and corrosion. As there was still iron staining on the surface of the tin which could not be removed further, the decidion was made between the conservator and Beamish museum to paint over these areas using acrylic. The small dent in the lid of the metal tin was reshaped carefully using pliers and the entire tin had a protective coating applied in order to try and prevent further corrosion and deterioration on the surface.

Finally the paper labels were backed with an appropriate material in order to help strengthen and stabilise them and they were re-adhered to the metal tin in their original positions using a suitable paper adhesive. They were held in place and slightly weighted down until the adhesive had cured.