November ’20

Rubber Be-Ro Mat

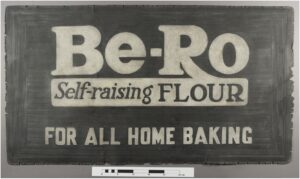

November’s ‘Object of the Month’ is a rubber Be-Ro mat advertising sefl-raising flour from Beamish Museum.

Object

The object is a rubber mat from Beamish museum advertising Be-Ro self-raising flour, and manufactured by Redferns Rubber Works.

The Be-Ro company was founded in Newcastle in the 1880s and became known by this name around 1910. Until the 1920s self-raising flour was considered an expensive luxury product, therefore Be-Ro staged a series of exhibitions and produced a free cookery book to encourage the use of this flour which led to Be-Ro becoming the best-known flour in Northern England. This cookbook has gone through many editions with slight changes to the design and contents, including changes to the logo. The design on the mat most closely resembles the logo used from the 1950s on, especially in the design of the ‘R’.

Redferns Rubber Works was founded in 1902 making rubber objects, initially rubber heels and later tires, electrical items and rubber mats (produced from around 1922). They were based in Hyde which is now in Greater Manchester. The company was absorbed into other companies in the 1960s, at which point the name changed, before closing completely in the 1980s. This mat likely dates from around 1950s-1960s.

The mat would be placed in the door of a shop and serve the dual purposes of cleaning shoes, and therefore protecting the floors, while also advertising a product sold within. The mat has a ridged design on the top which would aid in cleaning shoes and provide a non-slip surface.

Condition

- Heavy dirt and soiling on the surface

- One of the corners has folded over and is now misshapen

- There are signs of cracking on the surface of the mat.

Conservation

Initially the object was cleaned using a stiff bristled brush and a museum vacuum on low suction in order to remove dirt and reveal more of the surface underneath to determine whether there were any further issues with condition.

Due to rubber being a vulnerable material, dry cleaning methods are preferable to wet cleaning methods as solvents cause swelling and cracking. However, due to the level of soiling on the mat, it was thought wet cleaning methods would be required.

A stiff bristled brush with deionised water was used on the surface to dislodge further dirt and the surface was blotted with clean tissue to remove excess moisture and minimise potential damage. A surfactant was not used as these have been known to cause stress cracking and can cause additives to leach from the surface.

Slightly dampened cotton swabs were used to remove dirt from the white lettering as there were concerns that the colour might run and so this was the most controllable method for removing surface dirt.

The folded section of mat was fairly flexible and was able to be unfolded with no cracking or damage, however it required some additional treatment to ensure it remained flat. As such, the area to be flattened was weighed down with heated sand trays. Once cold, these were removed and the flattened section remained in its reshaped state.

Areas of cracking were stabilised using an appropriate consolidant for rubber in order to help prevent further deterioration of the surface. The rubber mat was then coated using Renaissance Micricrystalline wax in order to help provide some protection from the environment.

Stay tuned for next month’s object!