September ’22

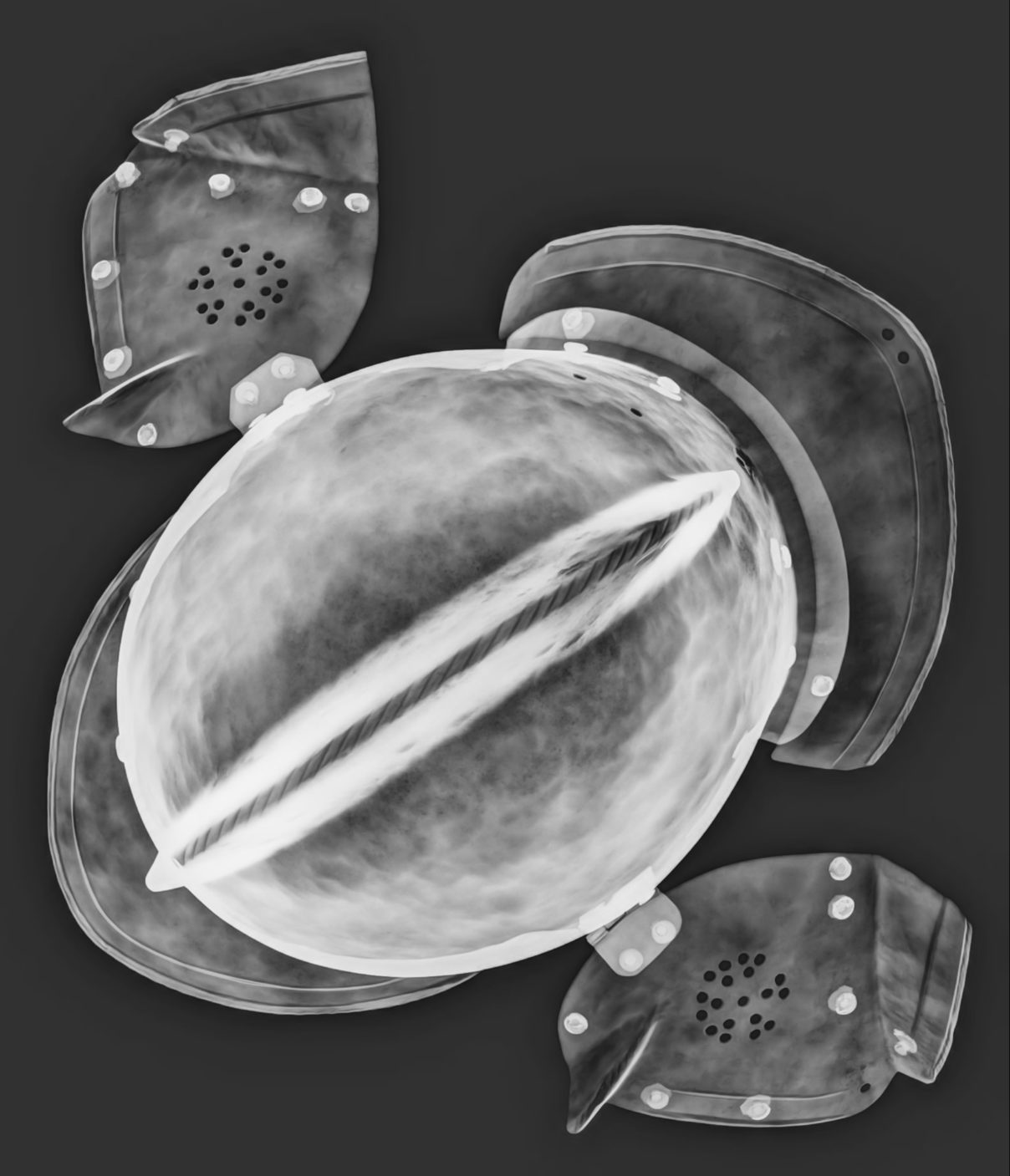

Burgonet Helmet

The object is likely a burgonet style helmet from the 16th Century, and forms part of the collections at Kiplin Hall. The burgonet helmet is characterised by a skull with a large fixed or hinged peak projecting above the face-opening On top of the skull piece there is a crest or comb running from front to rear. Either side of the face, and attached to the skull piece are cheekpieces which do not meet at the chin. A flange projects from the lower parts of the skull piece and cheekpieces to protect the back and sides of the neck. The burgonet helmet was common throughout Europe. It would have been accompanied by plate armour and was mostly worn by cavalry.

Kiplin Hall was built in the early 1620s as a hunting lodge by George Calvert, who served as Secretary of State to King James I. He was made Baron Baltimore and was granted the charter to found a colony in America, which would become the state of Maryland. His descendants built the colony and remained owners of Kiplin Hall until 1722.

Christopher Crowe bought the Hall from his son-in-law in 1722. He had made his fortune in Italy and many of the Italian items in the collection came from him. In 1818 Sarah Carpenter (nee Crowe) inherited Kiplin Hall and added the gothic style dining room.

Eventually Kiplin Hall passed to Bridget Talbot, the Hall’s final owner. Bridget supported soldiers on the Italian Front during WW1 and invented a waterproof torch for life-jackets. In 1971 Bridget set up a charitable trust to preserve Kiplin Hall, and this trust still run the Hall today.

Condition

- Iron corrosion covers the interior and exterior of the helmet

- There is evidence of a white bloom on the cheekpieces

- There are signs of hard concretions on the helmet

- The cheekpieces are loose and there are missing rivets

- There is evidence of a previous repair on the proper proper right cheekpiece

Conservation

The hard concretions and white bloom on the helmet were removed primarily with a scalpel and a dental pick as they could not be removed using other methods. Following this, a lubricant was applied to the inner and outer surfaces, and a brush specifically for corrosion removal was used to remove the thicker layers. The surface was then treated using a suitable abrasive material which removed the final areas of corrosion. The helmet was then treated using an appropriate solvent to remove all cleaning residues.

For the proper right cheekpiece, the historic wire was removed and straightened. The thread was cleaned using a suitable solvent, and the wire was replaced and tightened in order to limit further shifting and strain on the hinge. This was chosen as it was the least invasive option. The larger rivet on the same cheekpiece was treated using an appropriate consolidant fill as it would help to limit the strain and wear of the rivet on the helmet.

The missing rivet on the proper left cheekpiece was causing the piece to be misaligned and was putting strain on other areas of the helmet. As such a 6mm x 3mm nickel plated neodymium magnet was applied to the interior of the helmet to provide additional support of the hinge. The magnet was appropriately coated to prevent corrosion forming at the contact area.

The small remnants of leather on the bottom of the cheekpieces was treated using a specific leather consolidant to help prevent further deterioration.

Finally, the helmet was treated with Renaissance Microcrystalline Wax using the hot coating method. This would help to protect the helmet from future deterioration.

Stay tuned for next month’s object!